Validation

To illustrate the speed and reliability of my simulation app, FErez, in comparison to state-of-the-art tools in the same category, let’s consider an example. We'll take a look at a simple surface permanent magnet synchronous motor, such as the ILM25x08 from the German manufacturer TQ. These motors are sold as frameless, hollow-shaft stator-rotor kits, which makes it convenient to compare the datasheet specifications to simulation results.

Using only the available extended datasheet, 3D files, drawings, and pictures from the official website, it is possible to make some educated guesses about the machine’s design. Since the stator laminations are never shown, certain assumptions had to be made.

Picture from the official website and my guess on the stator design.

The rotor and stator diameters are provided in the datasheet. I assumed the stator teeth were parallel with rounded bottoms and a slot opening. For the rotor, to facilitate comparisons between software, I chose to use a segmented ring with diametral magnetization, rather than rectangular magnet blocks. I also assumed a winding of 19 turns per coil using AWG 27 wire. For the unknown electrical steel material, I used M330-35A. The resulting total weight is 22 g, which is reasonably close to the 25 g indicated in the datasheet, considering that the latter likely includes potting and a PCB.

In a star-serial connection and with a rated current of 4.3 A, we can extract the following values from the datasheet. Additionally, I gathered simulation results from colleagues who have access to Ansys Motor-CAD and Altair FluxMotor, two major references in electric motor design and simulation. These are steady-state simulations for a given current and can be compared across the three tools. FErez was run on an Apple M1 Pro CPU, while the other computations were performed on an Intel i9 processor from the same year (2020). The primary differences in the results arise from how the line resistance is calculated, with various methods used to account for end winding connections.

| Datasheet | FErez | Motor-CAD | FluxMotor | |

|---|---|---|---|---|

| Mechanical torque [mN.m] | 63 | 64.4 | 68.6 | 68.9 |

| Copper losses @20°C [W] | 10.3 | 10.31 | 10.86 | 9.767 |

| Torque constant kT @20°C [mN.m/A] | 14.7 | 14.97 | 16.43 | 16.02 |

| Motor constant kM @20°C [mN.m/√W] | 19.7 | 20.04 | 21.44 | N/A |

| Terminal resistance @20°C [mΩ] | 740 | 744 | 783 | 704 |

| Simulation time [s] | N/A | 4.6 | 28 | 75 |

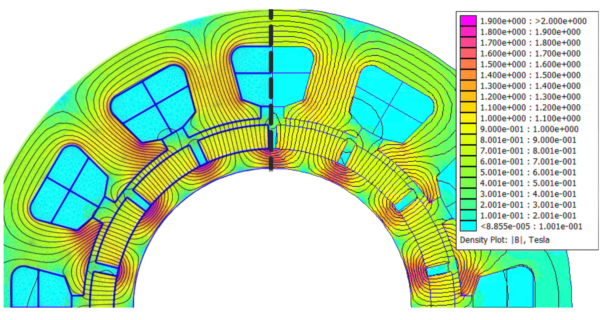

This table demonstrates that my app can simulate the main characteristics of an electric motor just as accurately, and faster, than these well-known software tools. Behind the scenes, I am using a custom-developed Finite Element Analysis (FEA) tool for magnetostatic computations. To further validate these results, we can directly compare the simulations one-on-one against FEMM, using approximately the same mesh. In this comparison, FErez completed the computation in 4.6 seconds, while FEMM took 6.5 seconds.

FErez on the left, FEMM on the right.

| FErez | FEMM | |

|---|---|---|

| Electromagnetic torque [mN.m] | 70.17 | 70.11 |

| Flux linkage A [𝜇Wb] | -1.731 | -1.727 |

| Flux linkage B [𝜇Wb] | -7.968 | -7.965 |

| Flux linkage C [𝜇Wb] | 10.49 | 10.49 |